How to identify the design bases of a Plant Design?

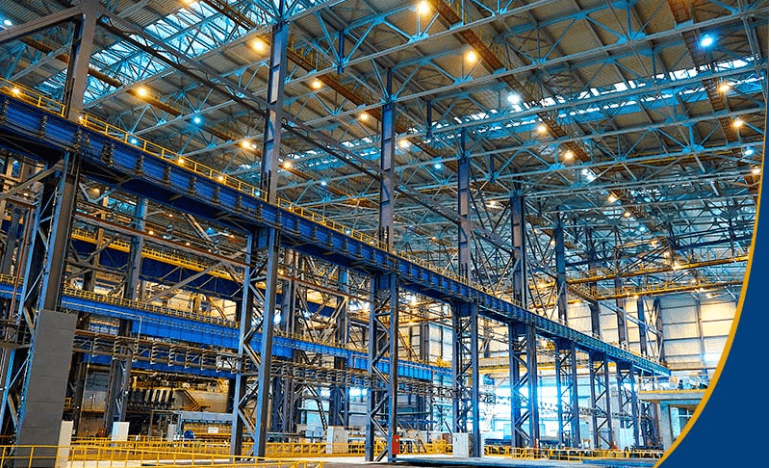

Companies must have a project design, for continuous development and survival. This work is led by specialists because they know how to channel physical space. They use the designs for new plants and for those that already exist, in this way they can expand and improve the premises. Industrial plant design should not be taken lightly because the pros and cons should be analyzed before making a decision, all alternatives should be examined before deciding where the factory should operate. In addition to taking into account costs, supplies, access, and infrastructure.

Industrial plant design should not be taken lightly because the pros and cons should be analyzed before making a decision, all alternatives should be examined before deciding where the factory should operate. In addition to taking into account costs, supplies, access, and infrastructure.

These are the objectives of the design of industrial plants:

● Reduced risk to health and increased the safety of workers.

● Increased production.

● The decrease in production delays.

● Shortening of manufacturing time.

● Greater ease of adjustment to changing conditions.

● The decreased risk to the material or its quality.

Bases of Design of an Industrial Plant:

1. Location of the Plant-

Ideally, the plant should be close to raw material stores and the consumer market. There must be an availability of labor, the use of adequate technology, suitable place to eliminate waste and in addition fire protection and noise reduction. Another elemental factor is the climate and the importance of systems such as electricity, drinking water, energy, communications. Social and cultural conditions must be taken into account, in addition to all legal and political issues.

2. Determining the size of the plant-

The size of the plant will be determined by its production capacity. Depending on the unit of time, this will be in volume, weight, value, or units of product produced per year, month, days in shifts and hours. One of the most important points will be the amount of raw material processed. The size of the project is usually specified concerning the production of a batch or mix of products. Two other important factors such as installed capacity and used capacity must be taken into account. Like the process and technologies used in the plant, both for goods and products and services.

3. The distribution of plants-

For long-term operations to be efficient, it will be important to determine the distribution of industrial plants. This implies, the capacity, the processes, the flexibility, and the costs, as well as the location of the plant. Remember that if the correct distribution is efficient, this will facilitate the costs and flows of the materials, as well as the personnel and information between the areas.

We can name some configuration designs :

- Aimed at distribution requirements for large and bulky projects: Fixed position distribution.

- Focused on small and multivariate productions: Distribution by processes

- Orders equipment and machinery to focus on the production of a single product or a group of related products: Cellular manufacturing systems.

- Seeks the best use of machinery and personnel for repetitive or continuous production: Distribution by-product